| Hint | Food | 맛과향 | Diet | Health | 불량지식 | 자연과학 | My Book | 유튜브 | Frims | 원 료 | 제 품 | Update | Site |

|

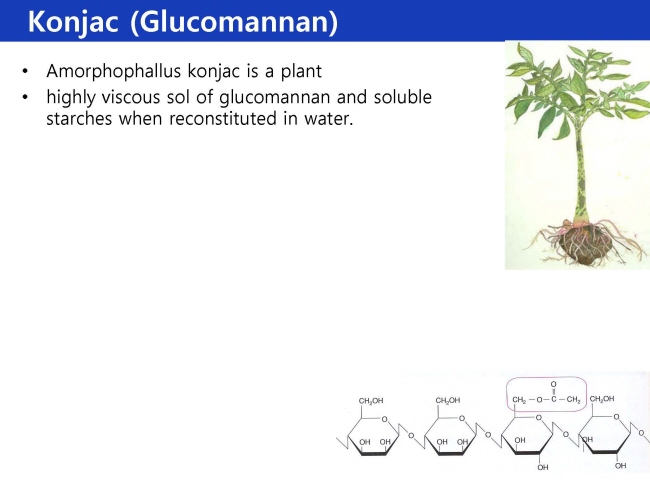

물성 ≫ 증점제 ≫증점제 종류 증점제 종류 : 증점제 총론 - Alginate : Alginate - Arabic : Arabic, Acacia - Carrageenan - Cellulose : CMC, MC, ... - Curdlan : Curdlan - 젤라틴 Gelatin : Gelatin - 젤란 Gellan - Guar : Guar - 곤약 Konjac - LBG : Locust, Carob - Pectin : Pectin - Tamarind : Tamarind - Xanthan 수산제품에서 활용 Konjac flour, which primarily contains glucomannan, is water soluble. It cannot form a gel alone, even if heated and cooled to room temperature due to the polysaccharide of konjac flour, which contains acetyl groups that inhibit the formation of a gel network. Introducing a mild alkali to a konjac solution, however, results in a strong, elastic gel that retains its structure under various heating conditions, such as boiling water, retort, and microwave [55,57]. The traditional Oriental method of preparing thermally stable konjac noodles requires that the konjac paste be soaked in mild lime water. Using rapid freezing to promote gelation, Wu and Suzuki [58] patented the use of konjac to simulate the strong texture of shellfish meat. Their method was to mix calcium hydroxide with surimi paste containing solubilized konjac slurry and then form it into a thin block before rapidly freezing. Frozen blocks were thawed in cold water before shredding into fibers. Owing to a strong off-odor generated from the chemical reaction of calcium hydroxide, extremely long washing is required. Therefore, production yield of the recovery is significantly low. However, fibers generated through this process are very strong and chewy, therefore making them retortable. Park [59] investigated changes of shear stress and strain values upon cooling, reheating, and freeze/thawing of surimi–konjac gels at various test temperatures. Konjac at 5% showed the ability to reinforce gel hardness by 8–10 times in both whiting and pollock surimi. When konjac flour was added at 4%, shear stress values were minimally affected by temperature, indicating addition into whiting and pollock surimi could produce temperature tolerant gels. These gels also exhibited an ability to maintain consistent shear strain values against freeze/thaw. Konjac up to 2% increased lightness of surimi gels as well, while the yellow hue gradually increased. Konjac gel prepared with a mixture of fillers is often frozen and sold as a frozen block (10 kg) in Asia as a yield extender. A study by Xiong et al. [60] determined that 1% of konjac glucomannan was as effective as conventional cryoprotectant (10% sucrose–sorbitol 1:1 w/w) for use in grass carp surimi. It is also noted that konjac gel imparts less stickiness to low-cost crabsticks containing a higher level of starch. However, further studies must be conducted to scientifically verify its function.   |

||||

|

|

|||